Installation and Disassembling

Placing the Moulds

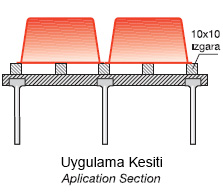

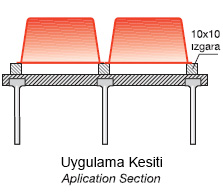

Polypropylene waffle moulds weigh below 25 kg, as they can be carried by a worker as per the European standards. For this reason, it requires relatively fewer number of workers to insert and /or assembly the moulds. No nails, screws are used. No sub coating such as plywood or wood is required either. A roof ridge should be placed on the scaffolding, and 10 x 10 cm grids that are a suitable range as per the mould are good enough. Products are placed and adjusted on the grids freely, and are pushed in between the main rib basis. This is how the assembling of moulds is completed.

When juxtaposed together, the lower parts of the moulds do not contact one another, and the lateral surface of the flanks is angular. The contacting surfaces will function as a gasket; therefore a well balanced tightening will prevent concrete leaks in between the ribs.

The personnel that will take part in the vibration at the time of concrete casting should be well-trained; and the vibrator diameter should not exceed 40 mm in accordance with the technique.

Şekil 1: 1xxx ebadındaki kalıplarda iki yanağın altına ve orta kısma gelecek şekilde ızgara konulması gerekmektedir.

|

Şekil 2: 8xx ve 9xx ebatlarındaki kalıplar için yanlızca iki yanağın altına ızgara konulması yeterlidir.

|

Lubrication

Once the moulds are placed, they can be lubricated with petroleum base or water base construction mould lubrications that are used for plywood or steel moulds. Even though the moulds are not lubricated, they will never engulf in concrete. In case of some applications, no lubrication is used at all, moulds are water-soaked before the concrete casting.

This method may result in local adhesion on the mould in the course of time. Even in this case the moulds can be removed off the concrete manually without requiring air.

Some of the companies approach the scaffolding from the bottom while removing off the concrete, and remove the waffle moulds at the end. Therefore they do not want the moulds to be removed while approaching the scaffolding from the bottom. And they prefer an application in the absence of lubrication. Half-and quarter-size moulds should be lubricated in all cases. Our company recommends lubrication with a standard mould lubricant in accordance with the technique.

Disassembling

No air pressure is required for disassembling. None of our products have a louver. Please do not drill one.

Depending on the size and depth of the mould, some of them might come loose as the scaffolding is loosened. The moulds that do not come off automatically should be pulled and removed with a hand tool without damaging the mould. No louver is required.

Half and quarter-size moulds should be removed by holding and pulling from the joints. As plastic welding is used for the production, the moulds may dislocate if pulled not with welding.

Depending on the method of lubrication, the moulds that are so removed can be cleaned with pressurised water if there are any concrete residues. In case of a short-term storage up to 1 or 2 days, the moulds are piled overlapped as they are put on the scaffolding. They are not placed onto the surfaces that face the concrete. Otherwise the surfaces can be scratched.

Please refer to the Storage section for long-term storage instructions.

Extra-Standard Sizes and Repairing

Products can be converted into half or quarter-size measures according to any desired sizes below the existing size during the initial ordering stage or after long years of usage. This is quick and cost efficient.. Half or full-size moulds (provided they are greater than the requested size) can e used for the conversion. Please refer to the Videos for watching half and quarter-size conversion.

Products are made of high impact resistant plastics, and are highly resistant to fall-off and impacts. However, as is known, they are still likely to be damaged and broken. All our products are repairable. Please get in touch with us for repairs. You can repair the products by using suitable tools and equipment especially in case of overseas construction sites.